MAGNABEND - FUNDAMENTAL DESIGN CONSIDERATIONS

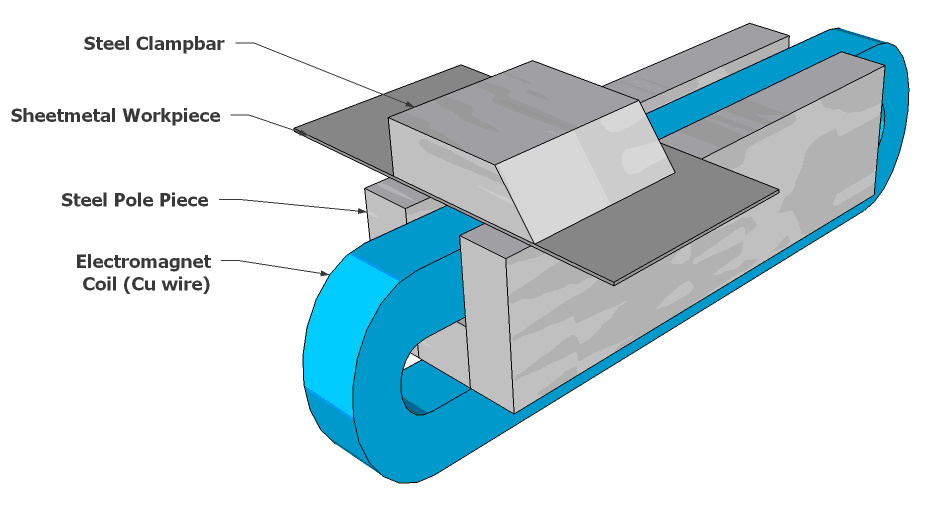

Basic Magnet Dhizaini

Muchina weMagnabend wakagadzirwa seine simba DC magineti ine shoma yebasa kutenderera.

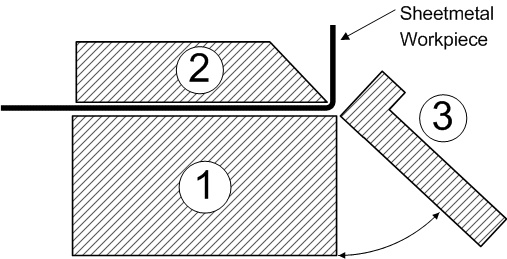

Muchina uyu une zvikamu zvitatu zvakakosha: -

Iyo magnet body inoumba hwaro hwemuchina uye ine electro-magineti coil.

Iyo clamp bar inopa nzira yemagnetic flux pakati pematanda egineti base, uye nekudaro inosunga iyo sheetmetal workpiece.

Iro danda rekukotama iro rakapinzwa kumucheto kumberi kwemuviri wemagineti uye rinopa nzira yekushandisa simba rekukotama kune workpiece.

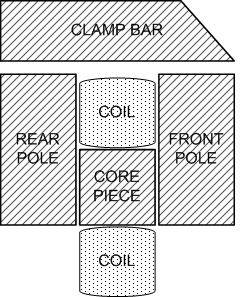

Magnet-Muviri Configurations

Yakasiyana masisitimu inogoneka kune iyo magineti muviri.

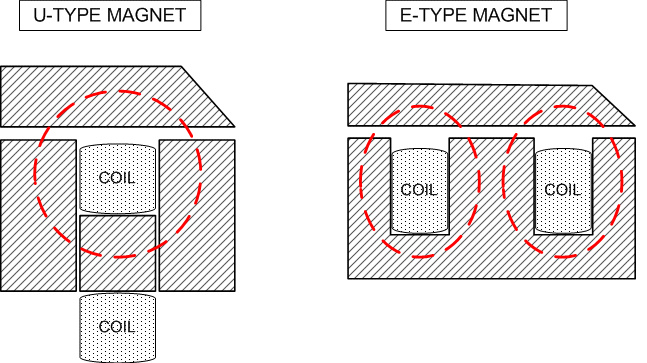

Heano maviri akashandiswa ese ari maviri kumashini eMagnabend:

Mitsetse mitsvuku yakadhirowa mumifananidzo iri pamusoro inomiririra nzira dzemagineti.Ziva kuti dhizaini ye "U-Type" ine nzira imwe chete yekuyerera (1 peya yemapango) nepo "E-Type" dhizaini ine 2 flux nzira (2 peya dzematanda).

Magnet Configuration Kuenzanisa:

Iyo E-mhando yekumisikidza inoshanda zvakanyanya kupfuura iyo U-mhando yekumisikidza.

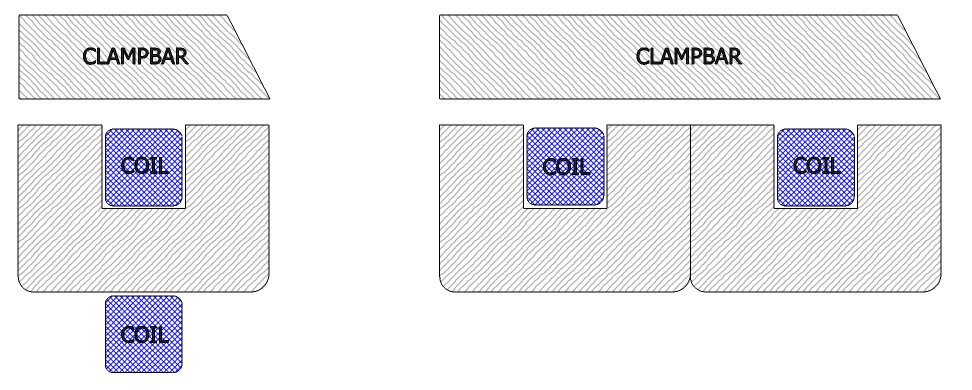

Kuti unzwisise kuti sei izvi zvakadaro funga madhirowa maviri ari pasi apa.

Kuruboshwe kune muchinjiko-chikamu cheU-mhando magineti uye kurudyi kune E-mhando magineti yakagadzirwa nekubatanidza maviri emhando dzeU-mhando.Kana imwe neimwe magineti kumisikidzwa ichifambiswa necoil ine yakafanana ampere-inotendeuka saka zvakajeka iyo yakapetwa-up magineti (iyo E-rudzi) ichava nekaviri kudarika simba rekurovera.Iyo inoshandisawo simbi yakapetwa kaviri asi isingachaiti waya yekoiri!(Kufungidzira kureba coil dhizaini).

(Iyo diki diki yekuwedzera waya yaizodiwa chete nekuti makumbo maviri ecoil ari kure zvakanyanya mu "E" dhizaini, asi iyi yekuwedzera inova isingakoshi mune refu coil dhizaini seyakashandiswa kuMagnabend).

Super Magnabend:

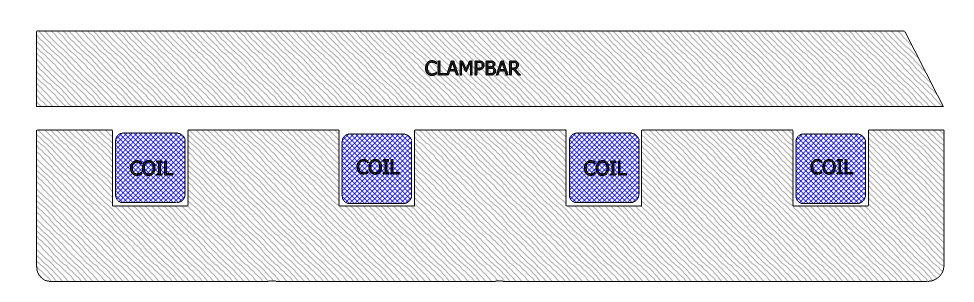

Kuvaka magineti akanyanya kusimba iyo "E" pfungwa inogona kuwedzerwa senge iyi kaviri-E kumisikidzwa:

3-D Model:

Pazasi pane 3-D dhizaini inoratidza kurongeka kwezvikamu muU-mhando magineti:

Mukugadzira uku matanda ekuMbero neKumashure zvimedu zvakaparadzana uye zvakanamirwa nemabhaudhi kuCore piece.

Kunyangwe musimboti, zvinogoneka kugadzira U-mhando yemagineti muviri kubva pachidimbu chesimbi, hazvizogoneke kuisa iyo coil uye nekudaro coil yaizofanira kukuvadzwa in situ (pamuviri wemagineti wakagadzirwa. )

Mumamiriro ekugadzirwa kwezvinhu zvinonyanya kudiwa kuti ukwanise kufambisa makoiri zvakasiyana (pane yakakosha yekare).Saka dhizaini yeU-mhando inonyatso raira chivakwa chakagadzirwa.

Kune rimwe divi iyo E-mhando dhizaini inozvikweretesa zvakanaka kumuviri wemagineti wakagadzirwa kubva pachimedu chimwe chesimbi nekuti coil yakafanogadzirwa inogona kuiswa nyore nyore mushure mekunge muviri wemagineti wagadzirwa.Iyo imwe-chimedu magineti muviri inoitawo zvirinani zvine magineti sezvo isina chero mapundu ekuvaka ayo angaderedzere magineti flux (uye nekudaro simba rekusunga) zvishoma.

(Mazhinji Magnabends akagadzirwa mushure me1990 akashandisa E-mhando dhizaini).

Kusarudzwa kwezvinhu zveMagineti Kuvaka

Iyo magineti muviri uye clampbar inofanirwa kugadzirwa kubva kune ferromagnetic (magnetisable) zvinhu.Simbi ndiyo yakachipa ferromagnetic zvinhu uye ndiyo iri pachena sarudzo.Nekudaro kune akasiyana simbi akakosha aripo ayo anogona kutariswa.

1) Silicon Steel : Yakakwirira resistivity simbi iyo inowanzowanikwa mune yakaonda laminations uye inoshandiswa AC transformers, AC magineti, relays etc. Zvinhu zvayo hazvidiwi kuMagnabend inova DC magineti.

2) Simbi Yakapfava : Nyaya iyi yaizoratidza yakaderera yakasara magineti ingave yakanaka kumuchina weMagnabend asi wakapfava mumuviri izvo zvinoreva kuti inogochwa nekukuvadzwa zviri nyore;zviri nani kugadzirisa dambudziko remagineti rasara neimwe nzira.

3) Cast Iron : Haisi nyore magnetised sesimbi yakakungurutswa asi inogona kutariswa.

4) Stainless Simbi Type 416 : Haikwanise kupihwa magineti yakasimba sesimbi uye inodhura zvakanyanya (asi inogona kubatsira kune yakatetepa inodzivirira capping pamusoro pemuviri wemagineti).

5) Stainless Simbi Type 316 : Iyi isiri-magnetic alloy yesimbi uye saka haina kukodzera zvachose (kunze kweiyo 4 pamusoro).

6) Yepakati Carbon Simbi, mhando K1045: Ichi chinyorwa chakakodzera kuvakwa kwemagineti, (uye zvimwe zvikamu zvemuchina).Iyo yakaoma zvine mutsindo mune se-inopihwa mamiriro uye zvakare inogadzira michina mushe.

7) Medium Carbon Steel type CS1020 : Simbi iyi haina kuoma seK1045 asi inowanikwa zviri nyore uye nekudaro inogona kunge iri sarudzo inoshanda pakuvaka kweMagnabend muchina.

Ziva kuti zvakakosha zvivakwa zvinodiwa ndezvi:

High saturation magineti.(Mazhinji simbi alloys anozadza kutenderedza 2 Tesla),

Kuvepo kwemasasi echikamu anobatsira,

Kupokana nekukuvara kwakaitika,

Machinability, uye

Mutengo unonzwisisika.

Simbi yepakati kabhoni inokodzera zvese izvi zvinodiwa zvakanaka.Yakaderera kabhoni simbi inogona kushandiswa zvakare asi haina kudzivirirwa kune kukuvara kwezvinoitika.Kune zvakare mamwe akakosha alloys, akadai sesupermendur, ane yakakwira saturation magineti asi iwo haafanirwe kutariswa nekuda kwemutengo wavo wakanyanya uchienzaniswa nesimbi.

Simbi yepakati kabhoni inoita asi inoratidza mamwe magineti akasara ayo anokwana kuita dambudziko.(Ona chikamu pane Residual Magnetism).

The Coil

Iyo coil ndiyo inotyaira iyo magnetising flux kuburikidza ne electromagnet.Simba rayo remagineti rinongori chigadzirwa chenhamba yekutendeuka (N) uye coil ikozvino (I).Saka:

N = nhamba yekutendeuka

I = ikozvino mumhepo.

Kuonekwa kwe "N" muchirevo chepamusoro kunotungamirira kune imwe pfungwa isiriyo.

Zvinofungidzirwa kuti kuwedzera huwandu hwekutendeuka kuchawedzera simba remagineti asi kazhinji izvi hazviitike nekuti kuwedzera kutendeuka kunoderedzawo ikozvino, I.

Funga nezvekoiri inopihwa ine yakagadziriswa DC voltage.Kana nhamba yekutendeuka yakapetwa kaviri ipapo kushorwa kwemhepo kunopetwa zvakare kaviri (mune coil refu) uye nokudaro ikozvino ichave nehafu.Iyo mambure mhedzisiro haina kuwedzera muNI.

Chinonyatso sarudza NI ndiko kupokana nekutendeuka.Saka kuwedzera NI kukora kwewaya kunofanirwa kuwedzerwa.Iko kukosha kwekuwedzera kutendeuka ndeyekuti ivo vanoderedza ikozvino uye nekudaro kupera kwesimba mucoil.

Mugadziri anofanira kurangarira kuti tambo yegeji ndiyo inonyanya kutema simba remagineti rekoiri.Iyi ndiyo inonyanya kukosha parameter yekugadzira coil.

Chigadzirwa cheNI chinowanzo kunzi "ampere inotendeuka" yecoil.

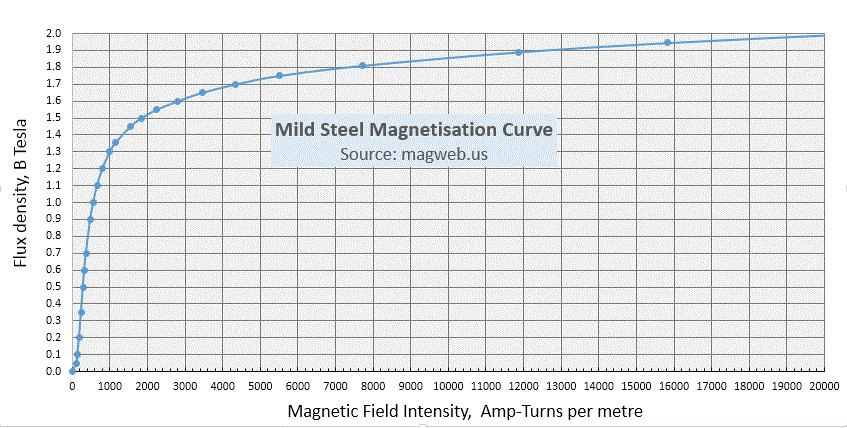

Mangani maAmpere Turns anodiwa?

Simbi inoratidza saturation magnetisation inosvika 2 Tesla uye izvi zvinoisa muganho wakakosha wekuti ingani simba rekumanikidza rinogona kuwanikwa.

Kubva pane girafu iri pamusoro tinoona kuti simba remunda rinodiwa kuti uwane flux density ye2 Tesla inenge 20,000 ampere-inotendeuka pamamita.

Ikozvino, kune yakajairika Magnabend dhizaini, iyo flux nzira kureba musimbi ingangoita 1/5th yemamita uye nekudaro inoda (20,000/5) AT kugadzira saturation, ingangoita 4,000 AT.

Zvingave zvakanaka kuve nematenderedzwa akawanda eampere kupfuura aya kuitira kuti saturation magnetisation igone kuchengetedzwa kunyangwe magepu asiri-magineti (kureva asiri-ferrous workpieces) akaunzwa mumagetsi edunhu.Zvakadaro akawedzera ampere anotendeuka anogona chete kuwanikwa nemutengo wakakura mukubvisa simba kana mutengo wewaya yemhangura, kana zvese zviri zviviri.Nokudaro kubvumirana kunodiwa.

Yakajairika Magnabend dhizaini ine coil iyo inoburitsa mazana matatu nemazana masere ekutendeuka.

Ziva kuti nhamba iyi haina kutsamira pakureba kwemuchina.Kana iwo magineti dhizaini akaiswa pamusoro pehurefu hwemakina saka inoraira kuti michina yakareba ichave nemachenu mashoma ewaya yakakora.Ivo vanozodhirowa huwandu hwazvino asi vanozove nechigadzirwa chimwe chete cheamps x kutendeuka uye vachave neiyo yakafanana clamping simba (uye yakafanana simba dissipation) pachikamu chehurefu.

Duty Cycle

Pfungwa yebasa kutenderera chinhu chakakosha zvikuru chekugadzirwa kweiyo electromagnet.Kana iyo dhizaini ichipa yakawanda yebasa kutenderera pane inodiwa saka haina optimum.Kuwedzera basa kutenderera kunoreva kuti waya yemhangura yakawanda ichadiwa (zvichizokonzera mutengo wakakwira) uye/kana kuchave nesimba shoma rekusunga riripo.

Ongorora: Iyo yakakwira duty cycle magineti ichave nekushomeka kwemagetsi izvo zvinoreva kuti ichashandisa shoma simba uye nekudaro ichave yakachipa kushanda.Nekudaro, nekuti magineti AKABATIDZA kwenguva pfupi chete saka mutengo wesimba rekushanda unowanzoonekwa seusina kukosha.Nokudaro nzira yekugadzira ndeyokuva nekuparara kwesimba rakawanda sezvaunogona kuwana kure maererano nekusapisa kupisa kwemhepo yekoil.(Iyi nzira yakajairika kune akawanda emagetsi madhizaini).

Iyo Magnabend yakagadzirirwa zita rekuita kutenderera kweinenge 25%.

Kazhinji zvinongotora 2 kana 3 masekonzi kuita bend.Iyo magineti ichabva yadzimwa kweimwe 8 kusvika ku10 masekonzi apo workpiece inoiswa patsva uye yakarongeka yakagadzirira kubhenda kunotevera.Kana iyo 25% yebasa kutenderera ikapfuudzwa ipapo kupedzisira magineti ichanyanya kupisa uye kupisa kwakawandisa kunofamba.Iyo magineti haizokanganiswe asi ichafanirwa kubvumidzwa kutonhora kweanenge maminetsi makumi matatu isati yashandiswa zvakare.

Chiitiko chekushanda nemichina mumunda chakaratidza kuti iyo 25% yebasa denderedzwa yakanyatsokwana kune vakajairwa vashandisi.Asi izvo vamwe vashandisi vakakumbira sarudzo yemhando yepamusoro yemagetsi emuchina ane simba rekurovera pamutengo wekuita kushoma kutenderera.

Coil Cross-Sectional Area

Nzvimbo yemuchinjikwa inowanika kune coil ndiyo inosarudza huwandu hwakawanda hwewaya yemhangura inogona kuiswa mukati. Nzvimbo iripo haifaniri kunge yakawanda kudarika inodiwa, inopindirana neinodiwa kutendeuka kweampere uye kupera simba.Kupa imwe nzvimbo yekoiri kunozowedzera saizi yemagineti uye zvinokonzeresa kureba nzira yekuyerera musimbi (inozoderedza kuyerera kwese).

Iyo nharo imwecheteyo inoreva kuti chero nzvimbo yecoil inopiwa mukugadzira inofanira kugara yakazara nemhangura waya.Kana isina kuzara saka zvinoreva kuti magineti geometry anogona kunge ari nani.

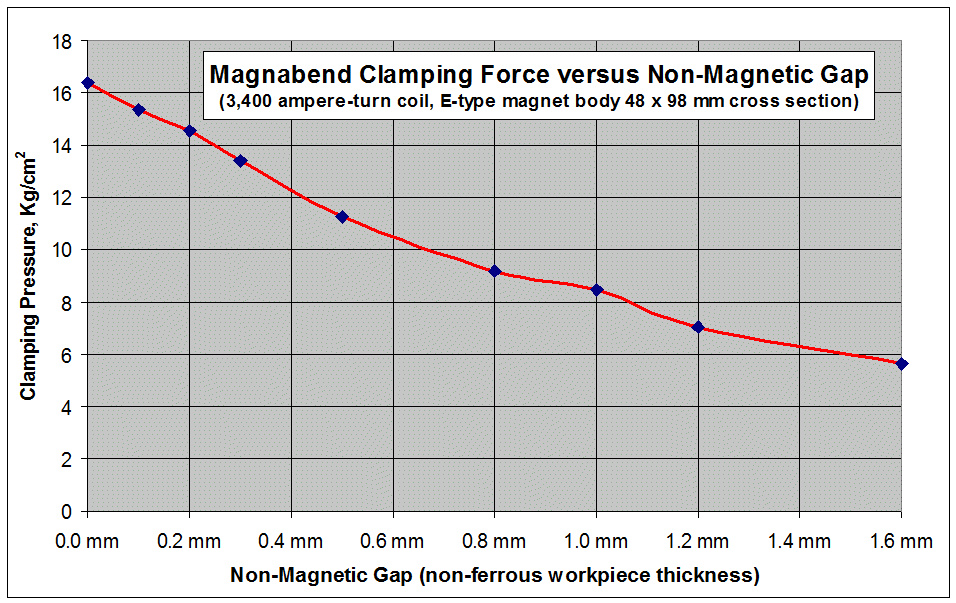

Magnabend Clamping Force:

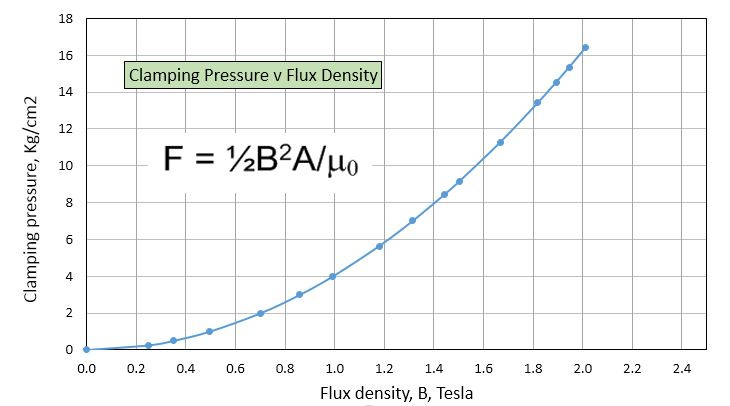

Girafu iri pazasi yakawanikwa nezviyero zvekuyedza, asi inowirirana nemaverengero edzidziso.

Iyo clamping force inogona kuverengerwa masvomhu kubva pane iyi formula:

F = simba muNewtons

B = magnetic flux density muTeslas

A = nzvimbo yemapango mum2

µ0 = magineti permeability nguva dzose, (4π x 10-7)

Semuenzaniso isu tichaverenga iyo clamping simba reiyo flux density ye2 Tesla:

Saka F = ½ (2)2 A/µ0

Kune simba pane unit nzvimbo (kumanikidza) tinogona kudonhedza iyo "A" mufomula.

Saka Kudzvanya = 2/µ0 = 2/(4π x 10-7) N/m2.

Izvi zvinobuda kusvika ku1,590,000 N/m2.

Kushandura izvi kuita makirogiramu simba rinogona kukamurwa ne g (9.81).

Saka: Kudzvinyirira = 162,080 kg / m2 = 16.2 kg / cm2.

Izvi zvinopindirana zvakanaka nesimba rakayerwa rezero gap rinoratidzwa pagirafu riri pamusoro.

Iyi nhamba inogona kushandurwa nyore nyore kuita yakazara clamping simba remuchina wakapihwa nekuchiwanza nenzvimbo yedanda yemuchina.Kumuenzaniso 1250E nzvimbo yedanda iri 125 (1.4 + 3.0 + 1.5) = 735 cm2.

Nokudaro iyo yose, zero-gap, simba raizove (735 x 16.2) = 11,900 kg kana 11.9 tonnes;9.5 tonnes pamita imwe yehurefu hwemagineti.

Flux density uye Clamping pressure yakabatana zvakananga uye inoratidzwa graphed pazasi:

Practical Clamping Force:

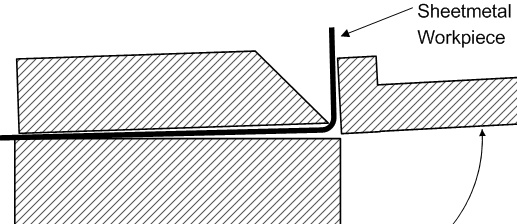

Mukuita iyi yakakwira clamping simba inongoonekwa chete kana isiri kudikanwa (!), ndipo pakukotama simbi dzakatetepa workpieces.Kana uchikotama maworkpieces asiri-ferrous simba richava shoma sezvakaratidzwa mugirafu riri pamusoro, uye (zvishoma zvinoshamisa), zvakare zvishoma kana uchikotama simbi dzakakora workpieces.Izvi zvinodaro nekuti simba rekusunga rinodiwa kugadzira kukona kwakakwira zvakanyanya kupfuura rinodiwa pakubhenda kweradius.Saka zvinoitika ndezvekuti sezvo bend ichienderera mberi kumucheto kwe clampbar inosimudza zvishoma zvichibvumira workpiece kuumba radius.

Kamukana kadiki kemhepo kanoumbwa kanokonzera kurasikirwa kudiki kwesimba rekusunga asi simba rinodiwa kugadzira radius bend radonha zvakanyanya kupfuura simba rekurovera magineti.Saka mamiriro akagadzikana anoguma uye clampbar hairegi kuenda.

Izvo zvinotsanangurwa pamusoro apa maitiro ekupeta kana muchina wava pedyo nemuganhu wawo.Kana yakatonyanya kukora workpiece ikaedzwa saka hongu iyo clampbar inosimuka.

Dhiagiramu iyi inoratidza kuti kana mupendero wemhino we clampbar wakaiswa radius zvishoma, pane kupinza, ipapo gaka remhepo rekukotama gobvu raizoderedzwa.

Hongu ndizvo zvazviri uye Magnabend yakanyatsogadzirwa ichave ine clampbar ine radiused mupendero.(Mupendero wakaiswa mupendero zvakare haunyanyi kukuvadzwa netsaona kana uchienzaniswa neyakapinza).

Marginal Mode yeBend Kukundikana:

Kana bend rikayedzwa pane yakakora kwazvo workpiece saka muchina unotadza kuipeta nekuti iyo clampbar inongosimuka.(Neraki izvi hazviitike nenzira inoshamisa; iyo clampbar inongoenda chinyararire).

Nekudaro kana iyo yekukotama mutoro wakangokura zvishoma pane kupeta simba remagineti saka kazhinji zvinoitika ndezvekuti bend inoenderera ichitaura nezve 60 madhigirii uye ipapo clampbar inotanga kutsvedza kumashure.Mune iyi modhi yekutadza magineti anogona chete kuramba kubhenda mutoro zvisina kunanga nekugadzira kupesana pakati pechishandiso chebasa nemubhedha wemagineti.

Musiyano weukobvu pakati pekutadza nekuda kwekusimudza uye kutadza nekuda kwekutsvedza kazhinji hauna kunyanya kuwanda.

Kusimudza-kutadza kukonzerwa neiyo workpiece inotsvedza kumberi kweiyo clampbar kumusoro.Simba rekurovera kumucheto kwemberi kwe clampbar ndiro rinoramba izvi.Kurovera kumucheto kumashure hakuna zvakunoita nekuti iri padyo neparikupinzwa clampbar.Kutaura zvazviri inongova hafu yesimba rose rekusunga rinoramba kusimudzwa.

Ukuwo kutsvedza kunorambiswa nechisimba chakazara chekusunga asi kuburikidza nekukwesha chete saka kuramba chaiko kunoenderana nekofivha yekukweshana pakati pechishandiso nepamusoro pemagineti.

Pasimbi yakachena uye yakaoma friction coefficient inogona kusvika 0.8 asi kana lubrication iripo saka inogona kunge yakaderera se0.2.Kazhinji ichave iri pakati pekuti iyo marginal mode yekutadza kubhenda kazhinji nekuda kwekutsvedza, asi kuedza kuwedzera kukweshera pamusoro pemagineti kwakawanikwa kusingakoshi.

Hukobvu Kukwanisa:

Kune E-mhando yemagineti muviri 98mm yakafara uye 48mm kudzika uye ine 3,800 ampere-turn coil, hurefu hwakazara hwekukotama kugona i1.6mm.Ukobvu uhwu hunoshanda kune ese simbi sheet uye aluminium sheet.Pachave nekushomeka kwekusungirira paaruminiyamu pepa asi inoda kushoma torque kuti ikotame saka izvi zvinoripa nenzira yekupa yakafanana geji kugona kune ese marudzi ese esimbi.

Panofanirwa kuve neamwe macaveats pane yakataurwa yekukotama kugona: Iyo huru ndeyekuti goho resimbi simbi rinogona kusiyana zvakanyanya.Iyo 1.6mm kugona inoshanda kune simbi ine goho redhisheni inosvika 250 MPa uye kune aruminiyamu ine goho redhisheni inosvika 140 MPa.

Ukobvu hunokwanisa musimbi isina tsvina hunosvika 1.0mm.Hunhu uhwu hwakanyanya kushoma pane kune dzimwe simbi zhinji nekuti simbi isina simbi inowanzova isiri-magnetic uye zvakadaro ine goho rakanyanya kushushikana.

Chimwe chinhu kupisa kwemagineti.Kana iyo magineti yakatenderwa kupisa saka kupokana kwecoil kunenge kwakakwira uye izvi zvinozoita kuti idhonze ishoma ikozvino nekuzotevera yakaderera ampere-inotendeuka uye yakaderera clamping simba.(Izvi zvinowanzoitika zvine mwero uye hazvigone kuita kuti muchina usangane nezvaunoreva).

Chekupedzisira, gobvu hukuru Magnabends anogona kuitwa kana iyo magineti muchinjiko chikamu chakaitwa chikuru.